This is a post about designing and building my own custom split keyboard. If you

are interested in the Ergogen/KiCad/gerber/firmware files, check out the

releases page on GitHub.

Motivation

A few years ago, I ventured into the rabbit hole of custom mechanical keyboards

and built my first one: the

KBD75 v3.

(Technically, my first build was the Atreus

about ten years ago, but I never ended up using it on a daily basis. So, I don't

count that.) I was satisfied with my KBD75, but occasionally, I found myself

curious about split keyboards due to their many

benefits. After much consideration,

I finally decided to try out the Lily58,

which seemed to be a very popular choice. I didn't want to go too minimal with a

layout like the Corne or

Kyria, since I could always

experiment with a smaller layout by disabling unnecessary keys. I ended up

purchasing the Aurora Lily58 kit

from splitkb. My main reason was that the PCB supported both encoders and

regular switches on the inner side (see the picture below). At that time, I

wasn't sure which I would prefer. I assumed it would be the switches, but I was

fundamentally wrong.

I used the Lily58 as my daily driver for about six months, and I was pleasantly

surprised. The ability to splay the keyboard was a natural fit for my wrists.

However, I wasn't completely satisfied with the physical layout; for instance,

the two outermost columns weren't perfectly aligned for my pinkies. Another

issue was the location of the thumb cluster. The two innermost keys were

difficult to reach for my thumb because they were positioned under the palm.

Additionally, the thumb cluster was arranged almost in a straight line, which

was unnatural. I would have preferred a more curved thumb cluster, similar to

what the Kyria keyboard has.

The well-served Lily58.

The well-served Lily58.

The number of switches felt right. Even though I didn't find much use for the

top row (the number row), I still prefer a higher switch count over relying

heavily on too many layers. Therefore, the 4x6+4 layout was a good fit for me.

As mentioned earlier, I found the two extra keys near the inside edge

inconvenient to use, and therefore, I will give encoders a chance next.

The Sofle v2, another very

popular split keyboard, solves some of these issues, but I began to wonder how

hard it could be to design my own keyboard — one that would be the perfect fit

for my fingers and needs. It turns out it wasn't too difficult.

Design Goals and Principles

I set down a few goals and principles for my new keyboard:

- Based on Lily58 and Sofle — The column positions are optimized for my

fingers rather than designing something entirely new. We'll stand on the

shoulders of giants.

- Keep It Simple and Stupid

(KISS) — This mainly means:

- No (RGB) LEDs or displays — I don't need them.

- No wireless — I have a pile of laptops on my desk and prefer using a

KVM switch rather than deal with

Bluetooth.

- No reversible PCBs — While this will slightly increase the cost, my OCD

can't handle that mess.

- Parametric design — There will naturally be many iterations, and I want to

avoid bugs caused by not updating something consistently.

- Avoid overly exotic layouts/key mappings — This won't be my only input

device, and I'll still use a standard QWERTY keyboard occasionally, like on my

laptop. So, I'd rather not introduce too much switching overhead.

- Easy access to both Ctrl and ⌘ keys — I use a mixture of different

operating systems and VMs.

Proof of Concept

Where would you start with your personal keyboard layout? There's a tool called

Ergopad that allows you to use an iPad to get a

rough idea of the optimal layout for you. However, I wanted to get a more

realistic feel for my design, so I ended up creating a 3D-printed rig to test

different layouts.

The custom split

keyboard rig.

The custom split

keyboard rig.

With this rig, I could easily iterate over different column offsets, make small

adjustments, physically press the keys, and repeat the process until I found the

perfect layout for my fingers. This hands-on approach was one of the best

aspects of the design process. I initially thought that adding a measurement

scale to the key plate sticks was a brilliant idea, but I still found myself

measuring each offset with a caliper to get the most accurate measurements.

This is also a natural point to discuss key mapping, as it closely relates to

the physical switch layout. Fortunately, I didn't have to invent the key mapping

from scratch since the overall layout is similar to the Lily58, and I already

have a key mapping that I've been using. I won't go into too much detail, as

it's still constantly evolving, but the main points are:

- Based on the

default

Aurora Lily58 key mapping.

- As a Neovim user (btw), the ESC key is placed

between the Shift and Tab keys.

- Since I use a combination of Mac/Linux/Windows, I really need both the Ctrl

and ⌘ keys, as mentioned previously. Therefore, I placed ⌘ on the left half

and Ctrl on the right half. Additionally, I've implemented

home row mods to allow easy

access to modifiers as well. However, I'm still experimenting with this, and

time will tell which approach feels more natural for me.

My current key map.

My current key map.

From PoC to PCBs

This post is not a tutorial on how to design your own keyboard, so I won't dive

too deep into the details of how to go from your desired layout to an actual

PCB. However, I want to discuss a bit about how I tried to parameterize and

automate the entire process to allow for

“reproducible builds” and

avoid mistakes like mismatched mounting holes across boards. The key component

for parametric design for custom keyboards is

Ergogen, a generator for custom layouts, including

KiCad PCBs. This tool converts a config file (YAML, JSON, or JS code) into DXF

drawings, KiCad files, and more.

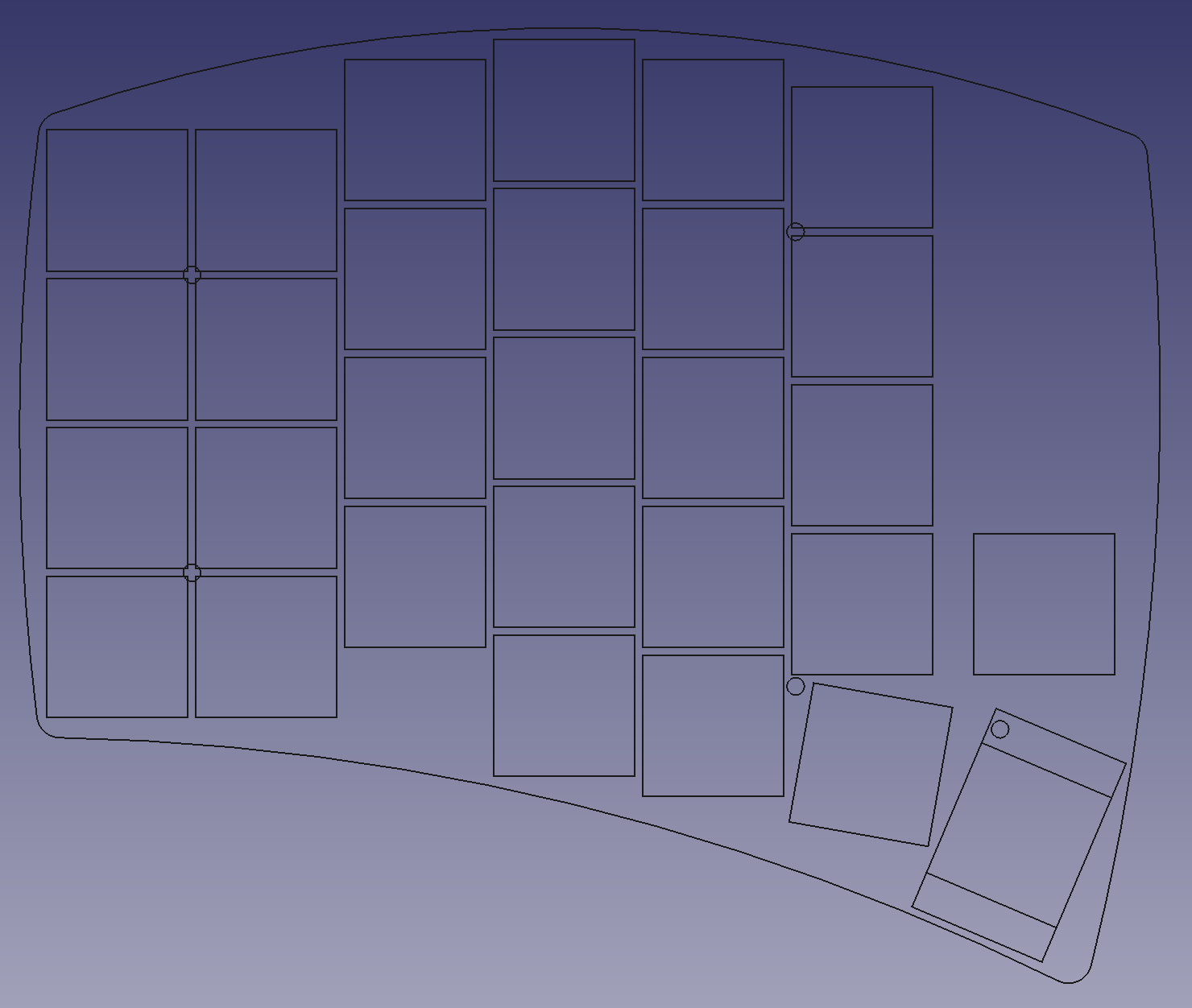

I converted the rough layout into the following overall design. Compared to the

Lily58, the pinky and index finger columns are offset further down, and the

thumb cluster is shifted more to the right and splayed out to match the natural

radius of my thumb.

The layout and outline

The layout and outline

I decided to go with a curved outline rather than the more common straight

lines. This added a bit of complexity since Ergogen didn't directly support

mirroring the outline shape. In addition, this produced some headache for the

connector placement since they typically require a straight edge.

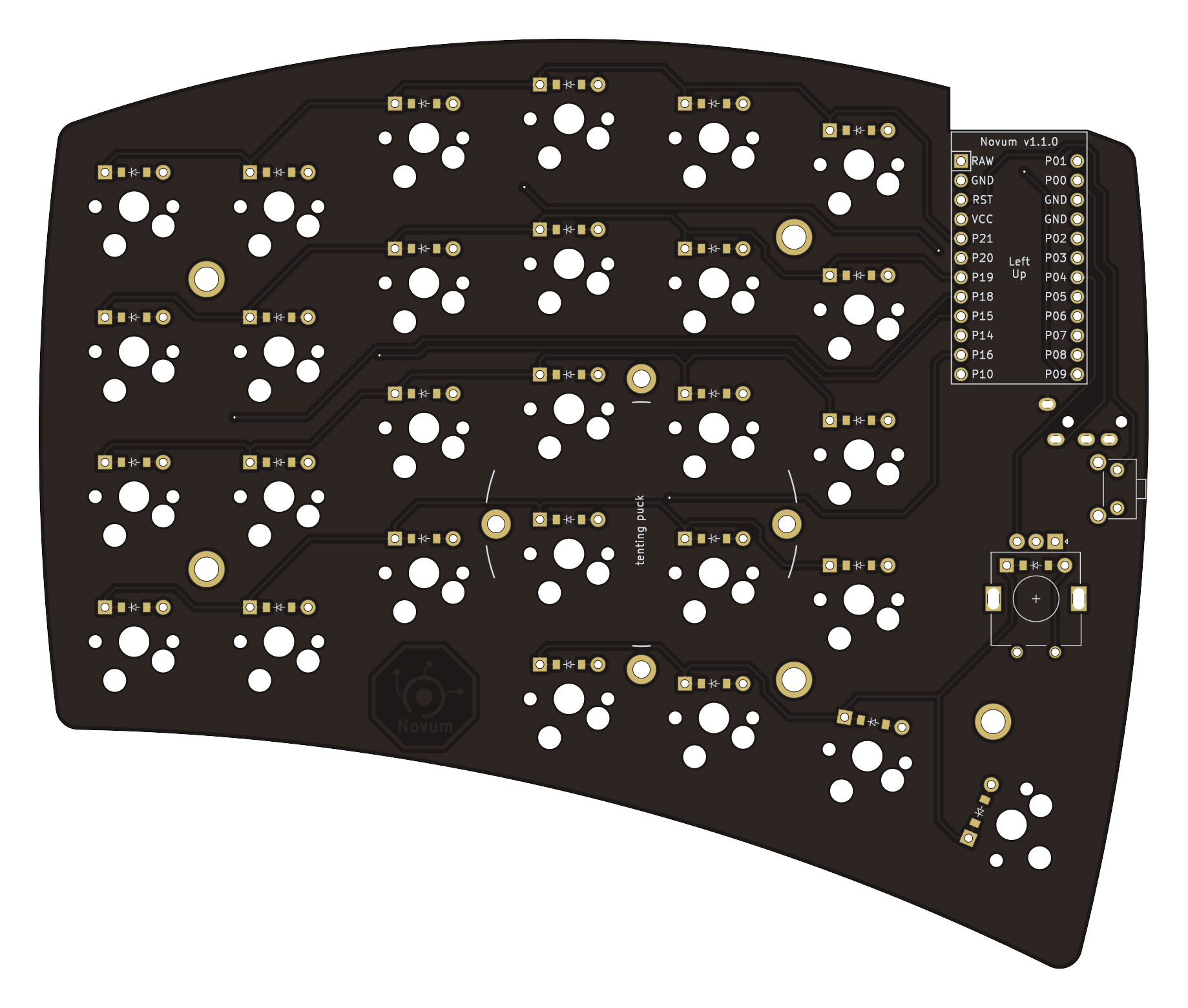

The next step was to generate the actual PCB files from that outline. I chose

the common sandwich design, with each layer of the keyboard (switch plate,

actual PCB, and bottom board) intended to be a 1.6 mm thick FR-4 circuit board.

This approach reduces costs and streamlines manufacturing, as it allows all

boards to be ordered from a single supplier, compared to a solution where the

switch plate and bottom board would be laser-cut acrylic for example.

The generated PCBs are still unrouted, which is unfortunate because ideally, we

would like to automate the entire build process. One obvious solution is PCB

autorouting; however, it tends to divide opinions. For this project, I took a

middle-ground approach, using a hybrid method where I hand-routed most of the

PCB and then let the autorouter handle the more

straightforward parts, like connecting diodes to switches. I wrote a few helper

scripts to

export and

import the

tracks from/to a KiCad board file. As a final step, I used

KiBot to automatically perform a Design

Rule Check (DRC) and generate Gerber and Drill files for

JLCPCB.

The left PCB.

The left PCB.

In addition to PCBs, the keyboard needs a firmware, and Novum supports both

Vial and

QMK. (However, the support is not still

merged into the main repos.) I went the extra mile here, and created the

script

which generates the QMK matrix from the KiCad PCB files. So, for example, the

physical switches will always be in the right place in Vial GUI.

All of the above is wrapped into a GitHub Action, which builds all necessary

files and either creates an automatic release or posts the generated artifact in

the PR's conversation.

Is it

possible to over-engineering your keyboard build process?

Is it

possible to over-engineering your keyboard build process?

You might ask why go through all this trouble. The main reason was to ensure

that all changes were propagated across all PCBs, and this actually saved me

multiple times. There were several moments when I wanted to make small

adjustments to edges, offsets, etc. Besides, you have to admit, it is also

super cool.

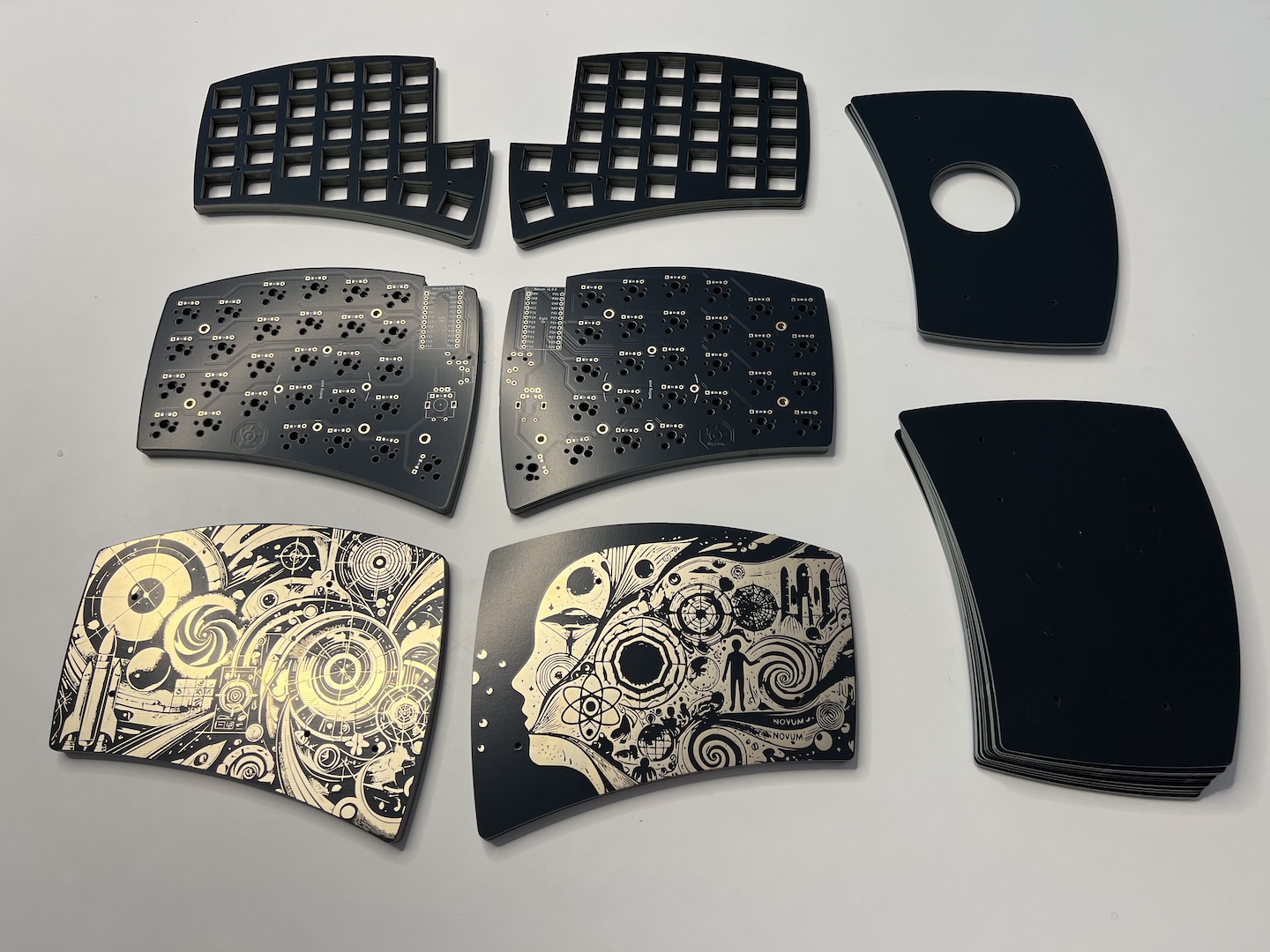

Bottom Boards Everywhere

The parametric design also allows for easily generating different options, and I

took advantage of this to create three separate bottom board designs. The first

one is just a plain board with the correct mounting holes. The purpose for this

board was just to be a backup if JLCPCB had refused the design shown below.

PCB art may be a niche art

form, but I find it fascinating to see the kind of art pieces you can create

with the extreme precision of industrial PCB manufacturing processes. So, I

decided to try my luck with JLCPCB and went All In with exposed solder mask

art on both sides for the second bottom board. I encountered a small problem

with the order form, as it couldn't produce a preview image, which prevented me

from adding the PCB to the cart. However, the design was successfully uploaded

to My Files, and after a few minutes, the preview was generated, allowing me

to order the board.

The third bottom board is a plain board with a hole for splitkb's

tenting puck. This provides an

elegant way to add tilt support to the keyboard. While I don't currently tilt my

keyboard, I figured that adding support for it doesn't cost much extra, so it

was worth including.

The ordered PCBs

The ordered PCBs

The Result

There isn't much to say about building the keyboard, as it's a very typical

build process. Since Novum doesn't have LEDs or other unnecessary components,

I'd even say it's simpler to build than most common keyboards. This build has

GAZZEW Boba U4

Silent Tactile (62 g) switches, and

linear

encoders. I re-used the Matt3o /dev/tty

keycaps and cables from

my old Lily58 build. So, here are pictures of the final result.

The Novum keyboard (Serial No. 0).

The Novum keyboard (Serial No. 0).

The side look.

The side look.

The keyboard in its natural

environment.

The keyboard in its natural

environment.

Final Thoughts

I'm happy with the result, and after a month of use, the layout feels very

natural — the switches are precisely where they should be :). Does this make

sense beyond being a hobby? Definitely not. But did I enjoy the process?

Absolutely.

The obvious next step is creating a proper case for the keyboard. However, I

still want to use the keyboard a bit longer before committing to a case. If I

decide to adjust the design (do I really need the number row?), it's cheaper to

order new PCBs rather than both PCBs and a case :D.

If you're interested and want to take a more in-depth look, check out the GitHub

repository.